Manufacturing Process

(Automotive Part)

SeAH Metal produces premium products through systematic management

of the manufacturing process from raw material inspection to product shipment.

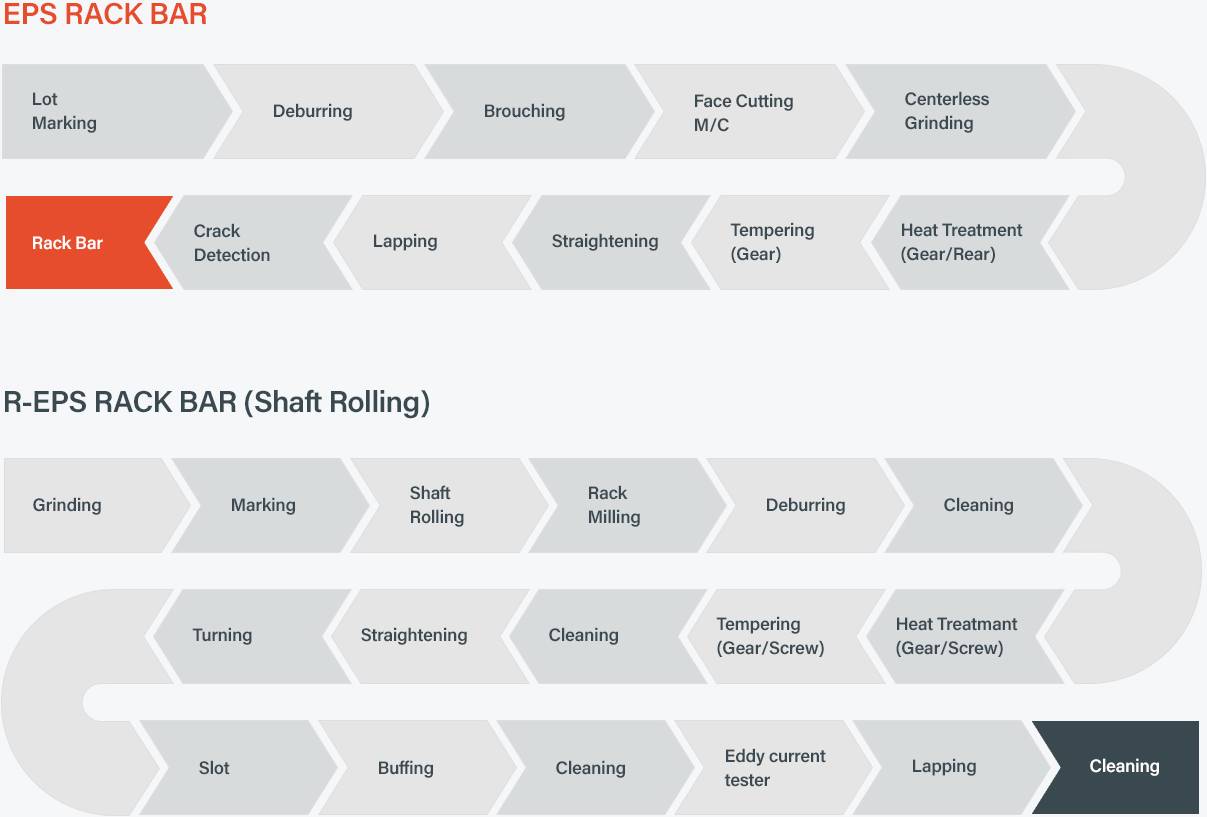

Process

RACK BAR

SeAH Metal's rack bars are used for automobile parts, ensuring safety and convenience through strict process control. Rack bars that have passed SeAH Metal’s strict quality control are widely recognized for their excellent quality by world-famous automobile manufacturers. Putting customer needs first, SeAH Metal continuously strives to invest and develop technology.

Manufacturing Process

Major equipment

-

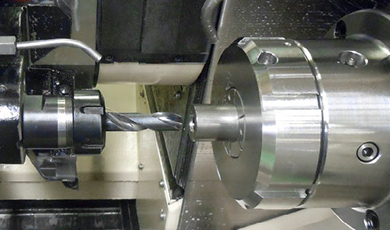

GUNDRILL

Gun drilling for machining, product lightweighting

-

CNC

Dual-sided CNC machining (drilling, tapping, boring)

-

STRAIGHTENER

Heat treatment deformation correction, straightness improvement

-

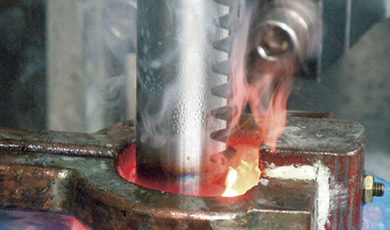

HEAT TREATMENT

Quenching and tempering heat treatment

-

CRACK DETECTION

Defect and crack microinspection testing

-

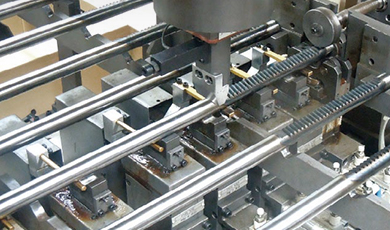

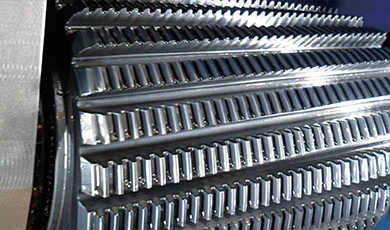

BROACH

Rack Gear broaching with automation

-

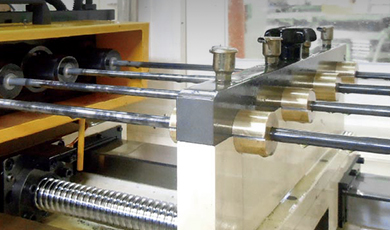

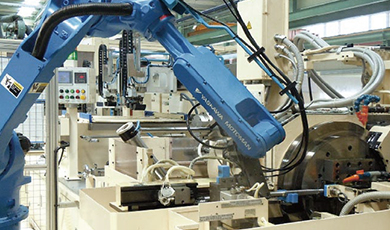

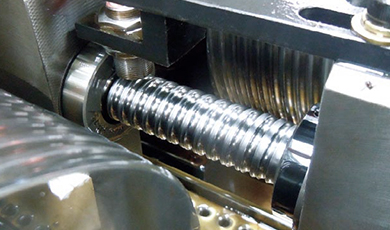

R-EPS ROLLING R-EPS

Ball screw machining (R-EPS)

-

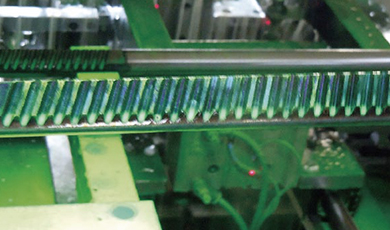

RACK MILLING

Rack Gear milling processing